- Home

- About Us

- Products

- CNC deep hole burnishing machine

- Deep hole drilling and boring machine

- Deep hole drilling machine

- Deep hole honing machine

- CNC deep hole gun drill machine

- Deep hole trepanning machine

- Special machine for wind turbine spindle machining

- Heavy duty deep hole drilling and boring machine

- Oil drilling collar processing machine

- Deep hole accessories

- Deep hole tooling series

- Lathe Rebuild Deep Hole Drilling Machine

- Deep hole drilling machine

- Success Case

- News Center

- Recruitment

- Sales network

- Contact Us

- CNC deep hole burnishing machine

- Deep hole drilling and boring machine

- Deep hole drilling machine

- Deep hole honing machine

- CNC deep hole gun drill machine

- Deep hole trepanning machine

- Special machine for wind turbine spindle machining

- Heavy duty deep hole drilling and boring machine

- Oil drilling collar processing machine

- Deep hole accessories

- Deep hole tooling series

- Lathe Rebuild Deep Hole Drilling Machine

- Deep hole drilling machine

|

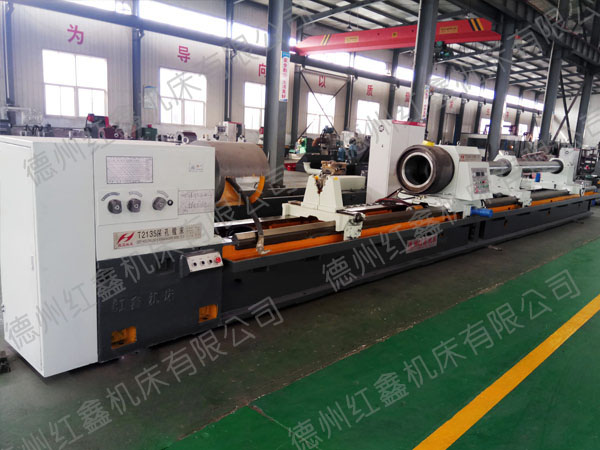

Spot sale of t2135 deep hole drilling and boring machine

|

| Technical Parameter |

T2235x3m deep hole drilling and boring machine from stock

T2135 deep hole drilling and boring machine is a deep hole processing equipment which mainly processes cylindrical workpiece, and the cutter and cutter bar do feeding movement. It can carry out drilling, boring and rolling processing, and can process through hole, step hole, blind hole, etc. the internal chip removal method is used in drilling. The tool feed adopts servo drive system to realize stepless speed regulation The machine bed is made of high-quality cast iron with strong rigidity and good accuracy. After quenching, the guide rail of the bed body has high wear resistance and good precision retention. It is widely used in mechanical hydraulic cylinder, special cylinder, coal cylinder, hydraulic machinery, high pressure boiler pipe, oil, military industry, electric power, aviation and other industries.

Main technical specifications and parameters of machine tool:

|

Technical specifications |

parameter |

|

T2135 |

|

|

Boring diameter range |

Φ100-Φ350mm |

|

Drilling diameter range |

Φ60-Φ80mm |

|

Machining depth range |

1-12m(One specification per 1 m interval) |

|

Working clamp diameter range |

200-450mm |

|

Spindle center height |

450mm |

|

Headstock spindle diameter

|

Φ75mm |

|

Front end taper hole of spindle |

Φ85mm,1:20 |

|

Spindle speed range and series |

30-500r/min Level 11 |

|

Diameter of drillbox spindle (optional) |

75mm |

|

Taper hole at the front end of drill box spindle (optional) |

Φ85mm,1:20 |

|

Speed range and steps ofdrill box (optional) |

80-350r/min 6 steps |

|

Feed speed range (stepless) |

5-1000mm/min |

|

Rapid speed of carriage |

2m/min |

|

Spindle motor |

30kw |

|

Hydraulic pump motor |

N=1.5kw,n=1440r/min |

|

Carriage rapid motor |

N=3kw,n=2880r/min |

|

feed motor |

N=5.5 kw (AC servo) |

|

Cooling pump motor |

N=5.5 kw,N=1460r/min(4 group) |

|

Rated working pressure of cooling system |

0.36MP |

|

Cooling system flow |

300L/min |

|

Rated working pressure of hydraulic system |

6.3MPa |

|

Maximum axial force on the pressure head |

6.3KN |

|

Maximum pushing force of pressure head on workpiece |

20KN |